rv air brake presure drop test|low pressure brake test : mfg The most important part of the air brake section was having to demonstrate to a examiner that I understood what happens when you depress the brake pedal with the engine .

Molly is working on her PhD looking at how mesquite herbicide treatment efficacy varies across levels of encroachment and what this means for vegetation recovery in dryland systems. She is broadly interested in the mechanisms underpinning the maintenance, invasion, and successful restoration of ecological communities, and developing data .

{plog:ftitle_list}

Resultado da Nathan Adewale Temitayo Tella (born 5 July 1999) is a professional footballer who plays as an attacking midfielder or right winger for Bundesliga club .

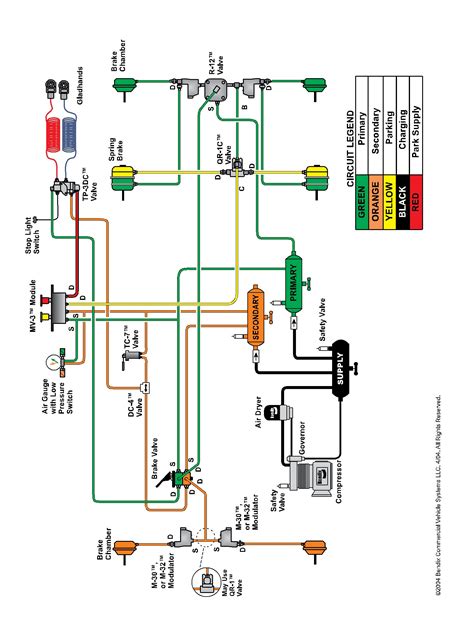

To perform this test, the vehicle must have enough air pressure so the low pressure warning signal is off. The engine may be on or off; however, the key must be in the “on” or “battery charge” position. Next, begin fanning off the air pressure by rapidly applying and . This should happen when air pressure drops to somewhere between 40 and 20 psi. If your system doesn’t work as indicated above, you need to call an air brake certified .Step 1 – Secure Motorhome. IMPORTANT - Chock rear wheels. Visually inspect air brake components. Start engine. Monitor air pressure. At >100 psi (690 kpa), shut off engine. .

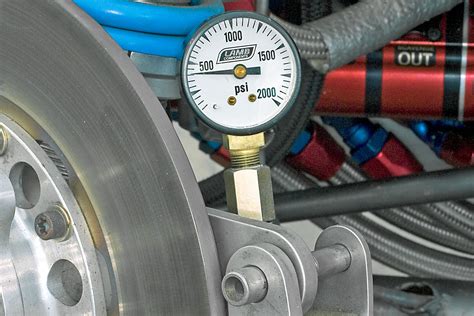

The air pressure should drop no more than 3 psi per minute. Excessive pressure loss indicates the brake system has a leaky fitting or component. Note that this assumes the air-ride suspension is fully inflated and .

Apply the brake pedal firmly (still with the parking brake is OFF). 7. After the initial pressure drop, the system should not loose any more than 3 PSI per minute. 8. With the . The most important part of the air brake section was having to demonstrate to a examiner that I understood what happens when you depress the brake pedal with the engine . Speaking of air pressure drop, I've noticed that when my coach sets for 2-4 days the front air gauge will be just below 60# which sets off the alarm but the rear gauge us usually .

Pushing in the yellow knob applies air pressure to the parking brake to release it. Pulling out the knob exhausts air pressure from the parking brake, allowing spring force to .Warns the driver that system air pressure is critically low. In modern air brake systems, the warning is both visual and audible. The warning activates when system pressure drops to 60psi (414kPa) or greater. In a number of . I noticed today that with full air pressure (130#)when I apply the brake pedal the pressure drops to about 105#..then builds back up to 130# If I stop and keep my foot on the . Winnebago "Drop Test" LouRobin: Winnebago Travel Trailers: 12: 07-20-2006 04:02 AM: . Pine Mountain RV Resort Pine Mountain, Georgia. Thousand Trails St Clair St .Air Compressor and Air System Pressure - You should be aware of common air pressure thresholds of your motorcoach’s brake system. The air pressure gauge tells you the adequacy of the air system. Air compressors typically have a “cut-out” pressure between 110 psi and 130 psi and a “cut-in” pressure about 20 psi lower. Air pressure .

To release the brake, first ensure there is air pressure, and then push the yellow park brake knob. Pressure will be applied to the front chamber of the dual-chamber spring brake to release it. So, in effect, a spring brake uses air pressure to release the brake, rather than apply it. As noted, spring brakes are found only on drive axles.

service brakes air pressure loss

To drive an RV with air brakes, allow greater stopping distance as it takes longer for the brakes to be applied when using air brakes. There will also be an air gauge on the dashboard showing the available air pressure. Never drive an RV is the air brake air pressure is low. So air brakes have a slight delay from the time your foot hits the .It’s a good idea to occasionally test your parking brake by making sure the brake is set, letting the air pressure build up, shifting into gear, and attempting to drive. . an alarm should sound. Keep pumping your brakes to test that the protection valve pops out between 40 and 20 psi. Now that those systems are working, stop shift into .

headspace gas analyzers

The Seven-Step Air Brake check is designed to test the governor cut-in and cut-out pressures, air pressure leakage, warning buzzer, brake valves and air pressure rebuild rates. Brakes off means the yellow and/or red valve is pushed in (on = valve out). 1. Engine on / Brakes on – check gauges to make sure governor cuts compressor off at 120 psi.page 10 quality heavy duty parts air brake system troubleshooting 04_26125_pg10-11.pmd 10 5/27/2004, 7:59 pm Everything that was asked was relevant to the operation of a vehicle like my MH. The most important part of the air brake section was having to demonstrate to a examiner that I understood what happens when you depress the brake pedal with the engine off and permit the air pressure to drop, eventually triggering the emergency/parking brake.

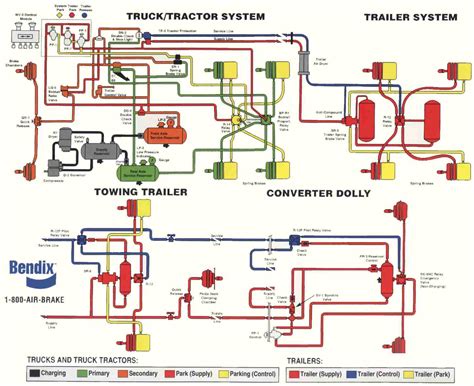

Then apply 90 psi or more with the brake pedal. After the initial pressure drop, if the air pressure falls more than three psi in one minute for single vehicles (more than four psi for combination vehicles), the air loss rate is too much. Check for air leaks and fix before driving the vehicle. Otherwise, you could lose your brakes while driving. Jeff Morgan explains how to Conduct a timed pressure drop test. It will verify, with 100% certainty, if a leak exists anywhere in the propane system. This te. All diesel and a few gas RV’s and motorhomes will use an air system to power things like the air brakes, the emergency brake, air suspension, and even automatic leveling. There’s an onboard air compressor that pressurizes two or more air tanks located under the RV towards the front.

motorhome air brake problems

Test air-loss rate by checking for audible air leaks and then observe the air pressure gauges with full air-pressure, the engine stopped, spring brakes released and service brakes applied. If the pressure drop in one minute exceeds the value specified for the vehicle, the air brake system is defective. Find out the 3 steps you need to follow to pressure test your RV for leaks, and how to prevent leaks! . Pressure testing an RV using air is an ideal way to check for leaks. By increasing the air pressure on the inside of the RV and covering the outside of the camper in a soap solution, bubbles can easily be spotted where leaks are present and .

If there is no electrical connection at the dashboard air valve, then there has to be an air pressure sensor on one of the air lines to sense the loss of air pressure. The park/emergency brake valve works by dumping air pressure from the brake lines, allowing the spring-activated park/emergency brake to automatically apply. After the initial pressure drop, the loss rate for single vehicles should be no more than 3 psi in one minute. If the air loss rate exceeds these figures, have the air system repaired before operating. Test Low Pressure Warning Alarm and/or Signal. Turn the key to the on position. Rapidly apply and release the service brake pedal to reduce air .

All vehicles with air brakes have a pressure gauge connected to the air tank. If the vehicle has a dual air brake system, there will be a gauge for each half of the system (or a single gauge with two needles). . if the power unit is equipped .

-Low air pressure in the brake system (below 60 psi). -Brake valve delivery pressure below normal. -Wrong size actuators and/or slack adjusters. -Failure of part of a dual air system. -If remote mounted brake valve, check linkage. 2.) Brakes Apply Too Slowly -Brakes need adjusting or lubricating. -Low air pressure in the brake system (below 60 . Hmmm may be a combination of several things.. The check valve at the wet tank (this is the tank that the air from the compressor goes to)(rare thing to happen normally see a failed check valve due to desiccant contamination caused by the air dryer not being serviced in a timely manner) Causes the tank air to back flow out of tank and back to the dryer.

Press the service brake (brake pedal) and hold it down for one minute. There should be no more than a 3 psi drop in pressure. (This checks for leaks with the system under pressure: the air lines, one-way check valves, and Diaphragms.) Check Audio and Visual Low Air Pressure Alarms/ Adjust Auto Slack Adjusters. Turn the engine back on and let . Yes, I understand that we are NOT commercial vehicles but the Fed Regs governing the equipment required in any truck tractor that is equipped with air brakes state you must have a warning device that "gives a continuous warning to a person in the normal driving position when the ignition is in the “on” (“run”) position and the air pressure in the service .

Thats possible.The gauges are in the dash,one says front air,the other rear air.I assumed they were reading the pressure for the entire air system.The front air is reading the high pressure and when it drops to zero the buzzer does sound but the gauge quickly goes to about 60 psi and then slowly builds back to 150 psi.

low pressure brakes

Ideally the air system pumps up and holds pressure until some normal function actually uses some air, e.g. brakes, suspension ride height leveling, air horn, whatever. On a smooth flat road, that should be near zero, if curves, dips, stop & go, etc, then air gets used and the compressor cycles as needed. 1. While driving the air presure will go down to about 100lbs thru brake usage and the Low Air warning light will come on. 2. Tap the the brakes a couple of times and the Air Pressure will come back up and start the cycle over. 3. The Air System does not appear to be leaking either in motion or stationary.

%PDF-1.7 %âãÏÓ 266 0 obj > endobj xref 266 36 0000000016 00000 n 0000002244 00000 n 0000002420 00000 n 0000002884 00000 n 0000002921 00000 n 0000003033 00000 n 0000003147 00000 n 0000004307 00000 n 0000004906 00000 n 0000005539 00000 n 0000006148 00000 n 0000006753 00000 n 0000007002 00000 n 0000007669 00000 n . 6. Apply the brake pedal firmly (still with the parking brake OFF). 7. After the initial pressure drop, the system should not loose any more than 3 PSI per minute. 8. With the engine off, ignition on and parking brake off, rapidly pump the brake pedal to bleed down the air supply.

I had a look at a 2000 American Coach with Spartan chassis today. When I held down the brake pedal, I could hear hissing from the front end and the front air pressure continued to drop for as long as the pedal was held down.

hs code for gas analyzers

hts for gas analyzers

WEBS2.E1 ∙ Family Dinner. Meech smuggles drugs from Las Vegas as a test to secure a new plug for BMF, a vicious gangster from the Brewster Projects, K-9; Terry begins his new .

rv air brake presure drop test|low pressure brake test